Search

Product categories

Latest News

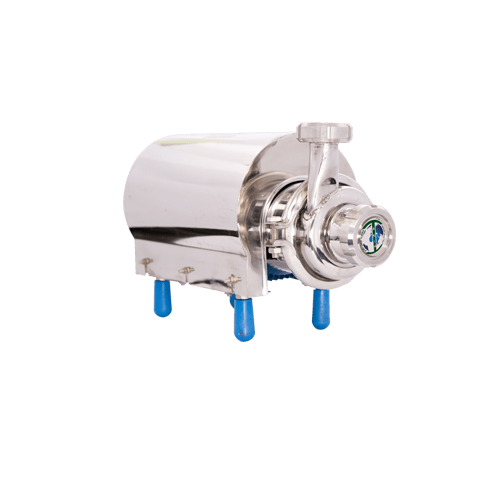

Centrifugal pump

technical specification:

| material: | All pump parts are made of steel |

|---|---|

| Electro-Motor: | Absorption gene and external motors if needed |

| case: | steel sheet |

| Capacity | 1 ton to 10 tons |

| Pressure | 0.5 to 8 times |

| manufacturing | Takin machine Radman centrifugal pump |

Please submit your comments about this product.

Centrifugal pump

A centrifugal pump is a device that receives mechanical energy from an electric motor or any other energy generator and transmits it to liquids. This mechanical energy increases the energy of the fluid leaving the device. Pumps are used to transfer fluid or transfer from one point to another.

In general, pumps are divided into two groups:

Positive displacement pumps:

In such pumps, the transfer of energy to the fluid is intermittent. In the design of positive displacement pumps, the fluid is drawn into the pump from one side and exits from the other side at the end of each cycle. This rotation or cycle in pumps depends on the type of rotors or the movement of the piston.

Dynamic pumps:

The transfer of energy to the fluid in dynamic pumps is permanent, which includes centrifugal pumps and axial pumps.

Centrifugal pump operation

The basis of the centrifugal pump operation is the conversion of the kinetic energy of the fluid into pressure. The centrifugal pump uses its impeller to increase the pressure of a fluid. The blades on the impeller are designed to flatten from the center, which reduces speed and increases pressure, allowing the centrifugal pump to generate high-pressure currents.

The operation of centrifugal pumps is to move the fluid in the opposite direction of the pump axis and then by moving away from the center of the pump axis to the inside of the thrust tube and finally with the difference between suction and thrust, the fluid moves rapidly to the pump outlet. he does.

Centrifugal pumps have a screw-shaped chamber called a shell in which one or more wheels are mounted on the shaft axis. Each of these wheels is equipped with a number of blades that transfer energy through these blades. A very important point about centrifugal pumps is that they must be vented before turning on, or in other words, priming the pump, which must be done before turning on the pump. That is, before the fluid enters, we must ensure that the trapped air inside the pump escapes. Centrifugal pumps are made in different sizes and dimensions and can be different for different uses depending on your use.

Factors that affect the purchase of the pump and the operation of the pump

Working fluid viscosity:

When buying a centrifugal pump, it should be noted that centrifugal pumps are designed to transfer fluids with low viscosity. Moving fluid density: The fluid density is its mass per unit volume. Fluid density directly affects the input power required to pump a liquid. In general, weight and density have a direct effect on pump performance.

Working temperature and pressure:

Temperature and pressure are an important point in any operation that must be carefully considered. Well, you have to explain at least one line.

Positive Suction Head (NPSH) and Cavitation -NPSH:

Liquid pressure on the suction side of the pump, which helps determine the amount of overpressure to prevent cavities.

But what is a hole?

The formation of bubbles in the cavity fluid is called the formation that occurs around the impeller and can seriously damage the impeller.

Fluid vapor pressure:

Fluid vapor pressure, the pressure that converts liquids to vapor at a certain temperature, must be determined to prevent cavitation.

Due to the diverse use of pumps, they are offered in different sizes and capacities depending on the type of application. You need to consider the pressure and volume to choose the type of pump according to your needs.

Disadvantages of centrifugal pump

There is energy loss in these pumps due to magnetic resistance.

At high flows, the efficiency of these pumps decreases.

These pumps have a low head.

They need to be sealed.

They are not able to pump high viscosity fluids.

Iron particles in the liquid (when using a magnetic drive) accumulate in the impeller and cause the pump to stop after a while.

Advantages of a centrifugal pump

One of the best advantages of centrifugal pumps is that there is no leakage in this type of pump.

The efficiency of these pumps is one hundred percent.

Has minimal friction losses.

Has the ability to pump hazardous liquids (such as acid, for example?).

I have seen in many foreign articles that saying these pumps has no sound, but this is a mistake and it must be said that the sound of these pumps is very low compared to other pumps.

It has the least amount of wear compared to other pumps.

There is no heat transfer in these pumps because there is a gap between the motor and the pump housing.

Fluid cannot enter the motor of these pumps due to the same distance between the chamber and the motor.

Main parts of centrifugal pump (centrifuge)

The centrifugal pump consists of approximately hundreds of components, the components of which are divided into two parts: the wet end and the mechanical end.

The wet end of the pump includes the part of the pump that determines the hydraulic performance of the pump.

The mechanical end consists of the part where the impeller is inside the chamber. The two include the shaft, the seal, the bearings and the shaft sleeve.

What are the components of each centrifugal pump designed for?

- Impeller: Used to increase kinetic energy

- Cover. Volute contains liquid and acts as a pressure relief vessel.

- Shaft: The shaft is a mechanical component for transferring torque from the motor to the impeller.

- Shaft sealing: Shaft sealing prevents pump fluid leakage.

- Bearings: Limit the relative movement of the shaft and reduce friction between the rotating shaft and the stator.

- Stator: The fixed part inside the motor is the stator and the part inside the stator that is rotating is the rotor. The stator consists of several layers of metal that are connected in the form of hollow cylinders.

Commissioning of centrifugal pumps

After the purchase of the pump, one of the most important factors in ensuring that a pump has a long life is its proper and principled operation.

Proper and principled operation of the pump

Launch it according to the manufacturer’s manual and instructions.

To start the pump, you must study and set up its setup and installation manual. Failure to follow the manual of the booklet can invalidate the manufacturer’s warranty.

Next, check the pump equipment and, if necessary, contact the manufacturer and ask what you are looking for and the manufacturer will give you the necessary instructions.

The next step is to service the pump sales specialist, which must be done by a specialist and a professional technician to provide the necessary services to you.

In the pump start-up phase, the pump sales specialist is those who have designed the pump equipment and are aware of the capabilities and sensitivities of the equipment and will be responsible for guaranteeing the equipment against defects.

Suitable pumps for food

Pumps used for food must be equipped with Clean-in-Place (CIP) and Sterilize-in-Place (SIP) functions.

There are several types of sanitary pumps that are suitable for use in the food industry.

Centrifugal pumps for various purposes such as oil; Drinks and milk, dilute dairy and fruit juices and acids such as vinegar and liqueurs such as mint and …

The most common applications of centrifugal pumps:

Energy generation industries

Water and sewage systems

Water supply and irrigation systems in agricultural industries

Water and gasoline sources

Food, pharmaceutical, chemical industry

Air conditioning systems

Various other industries ….

Types of centrifugal pumps

Centrifugal pumps are designed and manufactured in different models due to their various applications, all of which are based on centrifugal force.

Radial centrifugal pump:

In such pumps, the flow of fluids enters the pump parallel and exits perpendicular to the axis and with higher pressure in the outlet path. The shafts of this type of pumps are installed horizontally and vertically inside the pump based on their various applications and limitations. These pumps are used at high pressures and low flow rates.

Axial centrifugal pump:

Axial pump is another centrifugal pump. The way it works is that the liquid transfer enters the chamber in parallel and goes to the outlet in parallel and is finally thrown out of the outlet. Axial pumps are used in medium pressure and flow.

Semi-centrifugal pump:

These types of pumps are used in high flow rates. In such pumps, fluid and liquid water enter the chamber vertically and go to the outlet as a liquid. Semi-centrifugal pumps have a higher discharge capacity than radial pumps and also have more functions.

In general, it can be concluded that centrifugal pumps have various applications depending on factors such as design, type of construction, and are also made in accordance with international standards.

Reviews

There are no reviews yet.