Search

Product categories

Latest News

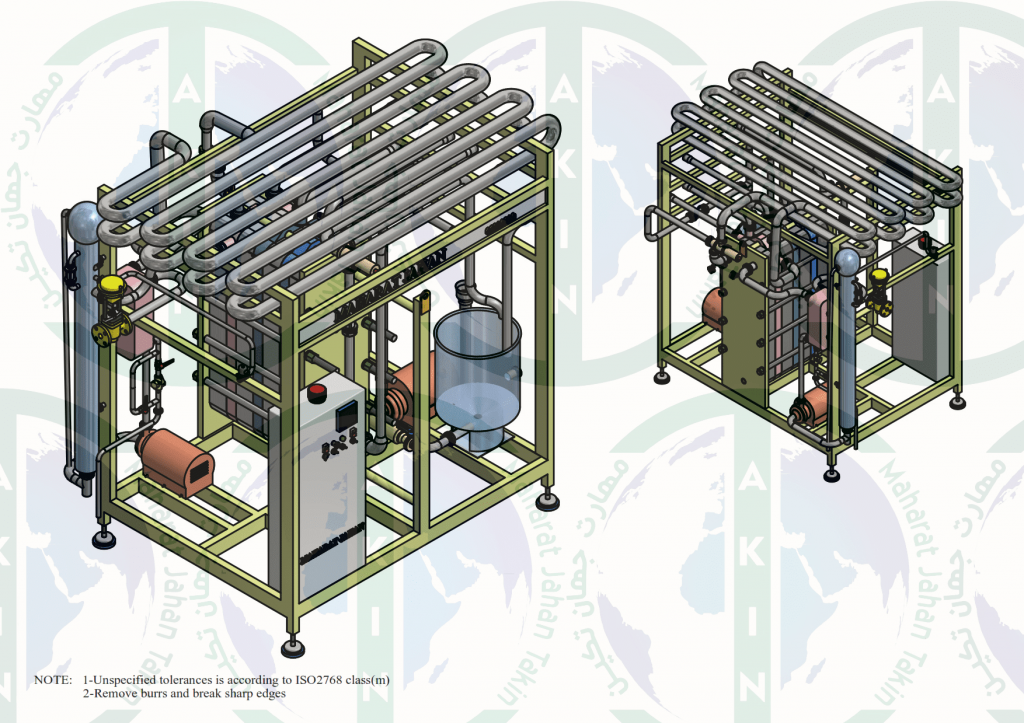

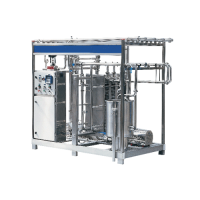

Tubular pasteurizer

technical specification:

| material: | Steel 304 -316 |

|---|---|

| Capacity | 500 liters to 30,000 liters |

| Pasteurized type | Manual (Pneumatic) – Automatic (PLC) |

| Appliances | Delta brand PLC |

| Device pump | Waterproof. Build in Takin Machine Radman |

| valves | Pneumatic and single construction of Takin Machine Radman |

| pipe | Seamless and European |

| Application | cream cheese. Cream . ketchup . Fruit puree. Pulp juices and …… |

Please submit your comments about this product.

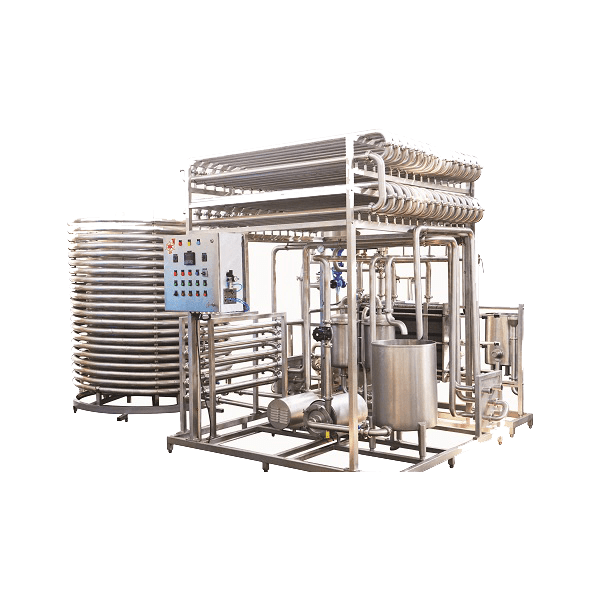

Tube pasteurizer

Pasteurization of food in food factories is the responsibility of pasteurization systems or pasteurizers. Plate heat exchangers are used to pasteurize milk. Tubular pasteurizers are used for pasteurization of thick and high viscosity liquids such as tomato paste, cherry jam, cream, ketchup, mayonnaise, yogurt, etc.

Tube pasteurizer is designed and manufactured from a capacity of 200 liters to 30,000 liters per hour. One simple example of these converters is the two-tube heat exchanger. This type of heat exchanger consists of pipes that are concentrically embedded inside another pipe. The flow of both flows between the two pipes and the inner pipe, respectively. Currents may be aligned or non-aligned (opposite to each other).

Heat exchangers are made of shell and tube with a circular cross-section mounted on a cylindrical shell.

One fluid flows inside the tubes and the other fluid on the side of the shell crosses with the tubes or along them and with the plate blades inside the shell and between us. The pipes are placed behind the pipes to keep the fluid in the path so that all the force of the fluid behind the pipe is transferred to the fluid inside the pipe.

The main design goals in these converters are to consider the thermal expansion of the shell and pipes and to clean the assembly more easily and at a lower cost in the method of manufacturing and producing them than others.

Application of tube pasteurizer

Viscosity foods and products that contain fiber and fruit pulp, such as fruit juices containing pulp, fruit concentrates, tomato juice and nectar, canned foods and jams, cream Yogurt, soft drinks, this type of pasteurizer is used. Tubular pasteurizers are designed and designed for pasteurization of liquids with larger particles (maximum 5-6 mm) in water soluble.

The role of pipes in pasteurizer operation

Tubular Heat Exchanger (THE) is used to heat or cool a product by exchanging heat between the inlet fluid and the fluid between the tubes, which is normally water. , Ice water or steam. Hot or cold liquid flows around the pipes inside THE and heat is transferred between the product and the environment.

The newest type of tube pasteurizer

Tube pasteurizers (tube by tube) are the latest examples of pasteurizers or pasteurizers and are used to pasteurize cream cheese, whipped cream, tomato paste and all types of condensed dairy products except pasteurized. Milk is used. This type of tube heat exchanger is designed to be connected to each other and in this part the first tube is heated and the second tube is cooled. Heating can be adjusted or stopped and kept cool according to the product up to 100 degrees Celsius and then up to the desired temperature.

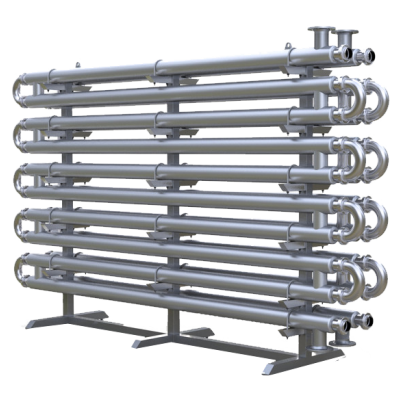

Tubular pasteurizer heat exchanger

A tube pasteurizer heat exchanger is a tube-shaped tube that forms a uniform circle inside a cylindrical shell. The operating system of this converter is such that milk or liquid to be pasteurized flows inside the pipes and the space around the pipes, which is an empty space, is filled with hot water vapor that the heat of hot steam penetrates into the body of the pipes. And raises the temperature of the liquid inside the tubes. Tube pasteurizer (tube pasteurizer) is designed and manufactured in several models of fully automatic, semi-automatic and ordinary. Tube pasteurizers are designed with two systems, low pressure tubular heat exchanger and high pressure tubular heat exchanger, which allow them to be easily cleaned and washed.

How should the quality of the pipes in the tube pasteurizer be

All tubular heat exchanger parts must be made of stainless steel. All pipes, valves, pumps, pipe holders, couplings are made of stainless steel. The base tube pasteurizer is heated by electricity. Another way is to use a boiler, solar and hot water.

What are the components of a tube pasteurizer

Tubular heat exchangers Unlike plate heat exchangers, they have no point of contact in the product channel. Tubular heat exchangers are designed and manufactured in two designs of double tubes or triple tubes. In terms of heat transfer, tubular heat exchangers are less efficient than plate heat exchangers. The tubes inside the tubular heat exchanger have spiral or corrugated surfaces that increase heat exchange.

Components of tubular heat exchangers

They are straight or curved U-shaped pipes that are able to transfer heat between fluids.

. The shell is produced from a bent or cylindrical tube or plate

. Plate or plates by which the pipes are fixed

Baffles that direct the flow out of the pipe but into the shell and support the pipes.

Nozzles that allow liquid to exit and enter the shell.

Holding the tube The retaining tube ensures that the pasteurized product is at the pasteurization temperature for a suitable period of time and that the temperature change does not exceed 1 ° F.

Holding Tube

In this section, food that has reached pasteurization temperature is stored at the same temperature for a period of time. Designed to ensure uniform product flow and prevent air pressure, with a minimum upward slope of 0.25 inches per foot. The length of time this product spends in the maintenance pipe is determined according to the pump schedule, the length of the maintenance pipe and the friction of the product surface. After flowing through the holding tube, the product contacts the indicator thermometer and the recording thermometer. The retaining pipe must be completely hygienic and installed on permanent supports.

Indicating Thermometer

The indicator thermometer in the pasteurizer (HTST) shows the exact and “official” temperature of the product. The indicator thermometer should be at the end of the retaining tube and be approximately the same size as the recorded thermometer, not less than 25 degrees Fahrenheit and not more than 0.5 degrees Fahrenheit.

Safety thermal limit recorder:

Safety Thermal Heat Recorder (STLR) automatically records the pasteurization time and position and position of the flow deflection device. This device is also able to control the position of the current deflection device. The recording thermometer should be 18 inches above the current deflection device.

Types of tube pasteurizers and their applications:

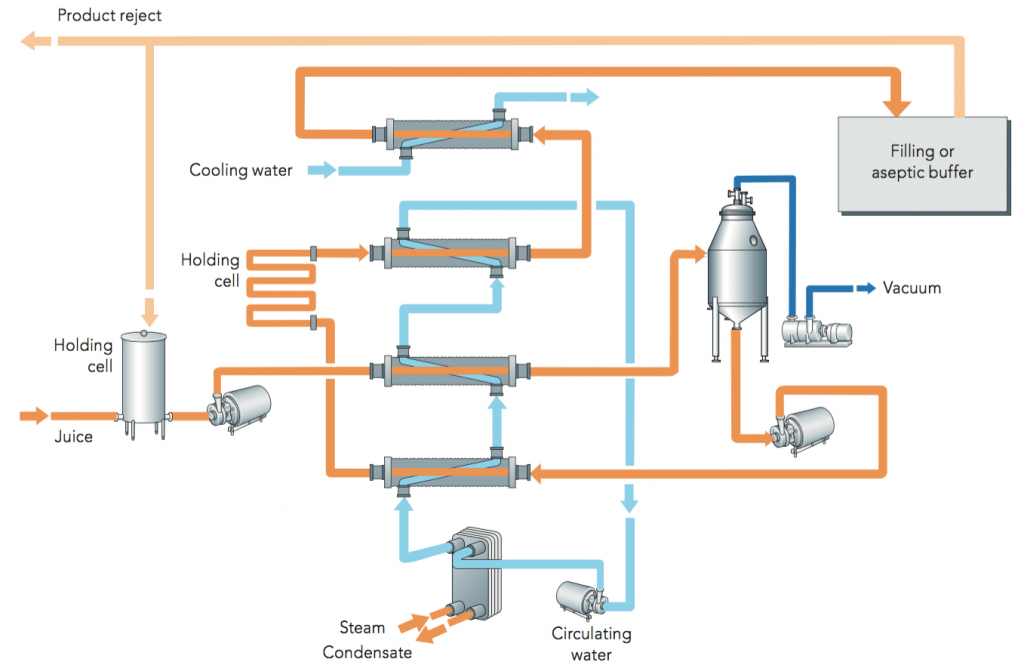

Tube pasteurizers are usually designed and built in three stages, the first of which includes energy-to-energy exchange, the second of which is heating, and the third of which is food cooling. It has reached the pasteurization temperature.

& nbsp;

Tubular pasteurizers with corrugated tubes:

These pasteurizers have a special structure: a multi-tube jacket heat exchanger that raises the surface for heat exchange, which is used to pasteurize liquids containing small parts and fibers. Takes.

Mono tube heat exchangers:

These heat exchangers are different from the above heat exchangers because they have only one heat exchanger per unit. This type of heat exchanger is used to process liquids that contain larger pieces, such as marmalade, orange pulp, peach cube, strawberry, mango, onion cube, red pepper pieces, etc.

& nbsp;

Circular tube heat exchangers:

These heat exchangers are used to pasteurize high viscosity products (above 2000 cps) such as concentrated tomato paste. The heat exchanger is the place where the product needs to be heated and cooled for pasteurization. This converter consists of a triple tube heat exchanger, where the product flows through the inner tube and the heat source in the surrounding tubes. / p>

& nbsp;

Disinfectants with steam injection and cooling with: (CAMERA FLASH)

For high capacity systems and continuous production (Flash Cooler) for sterile and cool Aseptic High viscosity concentrates are designed in which preserving the natural properties of the product and energy and energy consumption are priorities.

Concentrated products are heated by direct steam injection to the pasteurization temperature and kept at room temperature for the required time. They are therefore sent to a vacuum chamber where, using the flash effect, the product cools very quickly at an adjustable temperature between 15 and 38 ° C. This technology requires operational pressures that do not affect the natural properties of the product.

Reviews

There are no reviews yet.