Search

Product categories

Latest News

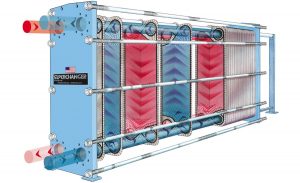

Heat exchanger (cooler plate)

technical specification:

Please submit your comments about this product.

Heat exchanger (cooler plate)

Heat exchangers are devices designed to transfer heat between two or more liquids, for example, liquids, vapors or gases with different temperatures in Radin Machine Company. Depending on the type of air conditioner plate used, the heat transfer process can be gas-to-gas, liquid-to-gas or liquid-to-liquid, and occurs through a solid separator, which prevents liquids from mixing together. From heat exchangers in dairy production lines and especially Plate pasteurizer machine <// a> is.

Heat exchanger components

There are many types of components that can be used in heat exchangers as well as a wide range of materials used to make them. The components and materials used depend on the type of heat exchanger and the intended application.

Some of the most common components used in the manufacture of heat exchangers (in single machine) including shell, pipe, coil, plates, fins and wheels adiabatic ( adiabatic). While metals are very suitable for the manufacture of heat exchangers due to their high thermal conductivity and are commonly used, such as copper, titanium and stainless steel cooler plates, other materials such as graphite, ceramic, composite or plastic, depending on Heat transfer program needs may have more benefits.

Heat transfer mechanism in the plate

There are two types of heat transfer mechanisms in the air conditioner plate – single-phase or two-phase heat transfer.

Single phase heat transfer

In single-phase heat exchangers, liquids do not change their phase during the heat transfer process, meaning that hotter and colder liquids are in the state of the material entering the heat exchanger. They become, they remain. For example, in water-to-water heat transfer programs, hotter water loses heat and then is transferred to cooling water and does not turn into gas or solid.

Two phase heat transfer

In the two-phase air conditioner plate of Tekin Machine Radman Company, liquids experience phase change during the heat transfer process. Phase shifts can occur in either the liquids involved or in both liquids, resulting in changes from liquid to gas or gas to liquid. Typically, devices that use a two-phase heat transfer mechanism require more sophisticated design considerations than devices that use a single-phase heat transfer mechanism. Some types of two-phase heat exchangers available include boilers, condensers and evaporators.

Boilers, condensers and evaporators

are heat exchangers that use a two-phase heat transfer mechanism. As mentioned earlier, in two-phase heat exchangers, one or more liquids deform during the heat transfer process, either from liquid to gas or from single gas to liquid.

& nbsp;

Condensers are heat exchangers that take a heated gas or vapor and cool it to a density, turning the gas or vapor into a liquid. On the other hand, in evaporators and boilers, the heat transfer process changes liquids from a liquid form to a gas or vapor.

Types of heat exchangers

Based on the specifications designed above, there are several types of heat exchangers available. Some common types in the industry include the following:

Shell and tube heat exchangers

Two pipe heat exchangers

Plate heat exchangers

Shell and tube heat exchangers

Shell and tube heat exchanger

The most common type of heat exchangers in Takin Machine Radman Company, shell and tube heat exchangers are made of a tube or a series of parallel tubes inside a cylindrical pressure vessel. Sealed (ie shell) is enclosed. These devices are designed in such a way that one liquid flows through the smaller tube (s) and the other liquid flows around its outer part and between it inside the sealed shell. Other design features available for this type of heat exchanger include vane pipes, single or two-phase heat transfer, countercurrent, co-current or cross-current settings, and single, double or multiple pass settings. p>

Some types of shell and tube heat exchangers include helical heat exchangers and double-tube heat exchangers, and some applications include preheating, oil cooling and steam generation. .

Two pipe heat exchangers

A type of shell and tube heat exchanger, two-tube heat exchangers The simplest design and configuration of a heat exchanger is used, consisting of two or more concentric cylindrical tubes or tubes (one Pipe is larger and one or more pipes are smaller). According to the design of all shell and tube heat exchangers, one fluid flows through the smaller tube (s) and the other fluid flows around the smaller tube (s) inside the larger tube.

Design requirements for double tube heat exchangers

Double pipe heat exchanger design requirements include the specifications of the return and indirect contact types mentioned earlier because liquids are separated and flow through their ducts during the heat transfer process. However, there is flexibility in the design of two-pipe heat exchangers, as they can be designed with simultaneous or countercurrent arrangement and used modularly in series, parallel or parallel series configurations within the system. For example, Figure 4 below shows the heat transfer in a heat exchanger isolated from a double tube with a stirrer flow configuration.

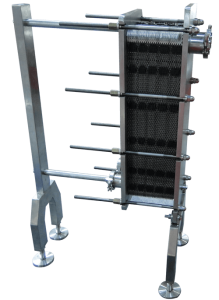

Plate heat exchangers

Plate heat exchangers, also known as plate type heat exchangers, are made of several narrow, corrugated plates that are bonded together. Each pair of plates creates a channel through which a liquid can flow, and the pairs are stacked on top of each other – via bolts, solder or welding – in such a way that a second passage It occurs between pairs through which another fluid flows.

Ballet plate or pillow plate heat exchangers

The standard plate layout is also available with some modifications, such as fin plate heat exchangers or pillow plate heat exchangers. Plate fin converters use vanes or space between plates to allow multiple current settings and more than two liquid streams to pass through the device. Pillow plate heat exchangers apply pressure to the plates to increase the heat transfer efficiency of the plate surface. Some other types available include plate and frame heat exchangers, plate and shell and helical plate heaters.

Other types of heat exchangers

Heat exchangers are used in a variety of applications in a wide range of industries. As a result, different types of heat exchangers are available, each tailored to the needs and specifications of a particular application. In addition to the types listed above, other types available include air-cooled heat exchangers, fan heat exchangers, and adiabatic wheel heat exchangers.

Some of the factors that industry professionals should keep in mind when designing and choosing a heat exchanger are:

& nbsp;

Type of liquids, fluid flow and their properties ( viscosity , alkalinity or acidity, etc.)

desired thermal outputs

Capacity limit

Costs

Liquid type, flow and their properties

Plate or plate air conditioner heat exchanger

Plate heat exchanger (PHE) is a special design suitable for heat transfer between medium and low pressure liquids. A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. These plates are compressed by two pressure plates in a plastic package. Inside a plate heat exchanger, fluid paths are alternately placed between the plates, allowing the two liquids to interact several times in a small area, but not to mix. Plate heat exchangers (PHE) are the most cost-effective way to cool milk.

Application in dairy production lines

Fresh milk is exposed to germs immediately after milking. In a plate cooler (plate heat exchanger or plate cooler), the milk cools down quickly. Germs can rarely grow in the cold environment of milk. However, in addition to health goals, pre-cooling also saves on energy costs. Fresh milk, which is 37 ° C, is cooled to a temperature of 14-20 ° C (depending on the water temperature) and therefore cooled much faster to the final desired temperature. The water pipe or well water in the place is used as a cooling material. The manufacturer recommends a 2: 1 ratio of milk to water.

Cooling tap and water in a plate cooler

Cooling milk and water in a plate cooler (plate heat exchangers) do not mix with each other in any way. Reliable seals are installed between the components of the device to prevent the combination of water and milk. The stainless steel structure ensures the long life of the system. At the same time, the plate cooler (plate heat exchanger) can withstand pressures up to 4 times and can be easily reinforced with plate spare parts.

Types of plate heat exchangers

There are four main types of PHE:

Gasketed washer

soldered brazed

welded

semi-welded

Washer plate heat exchanger or washer plate converter basically consists of a number of thin rectangular plates that are sealed around the edges by washers and glued together in a frame.

Advantages of using a plate heat exchanger or air conditioner plate

One of the unique advantages of Radman Raden Machine PHE is its flexible thermal design (plates can be easily added or removed to meet different heat or processing needs) , Ease of cleaning to maintain strict hygienic conditions, good temperature control (required in refrigeration applications), and excellent heat transfer mechanism.

Advantages of a plate heat exchanger in a few sentences:

Easy to clean (remove the bolts and pull back on the movable frame. The plates can then be inspected and cleaned)

Upgradeability (saves time and money)

High efficiency (due to compressed patterns in relatively narrow plates and slits, very high turbulence is achieved at relatively low fluid velocities)

Compact size

Fast heat transfer process

Multiple tasks in one unit (can be created in sections, separated by more complex divider pages or separator frames)

Less scale (smooth surface of the screen reduces scale)

Lower costs

Buy Radman car heat exchanger plate or single cooler plate

Tekin Machine Radman Company, according to the needs of food industry, by designing and manufacturing heat exchangers with excellent quality and reasonable price, has been able to take a step towards efficiency in the production and manufacture of dairy and juice machines. Search to buy heat exchangers or the same plate of Radman car single coolers, please contact the phone numbers of the site.

How to buy and guarantee the product

To purchase this product, please contact the sales unit of Radman Machine Radan. Please note that this product has one year warranty and ten years after-sales service.

Reviews

There are no reviews yet.